Products

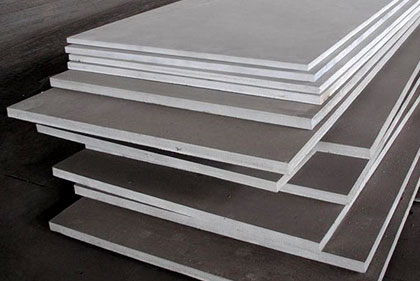

HOT ROLLED PLATES

Hot rolling is a metalworking process that occurs above the re-crystallization temperature of the material. After the grains deform during processing, they re-crystallize, which maintains an equated microstructure and prevents the metal from work-hardening.

The starting material is usually large pieces of metal, like semi-finished casting products, such as slabs, blooms, and billets. If these products come from a continuous casting operation the products are usually fed directly into the rolling mills at a proper temperature. In smaller operations, the material is at room temperature and must be heated. This is done in a gas- or oil-fired soaking pit for larger work pieces and for smaller work pieces induction-heating is used. As the material is worked the temperature must be monitored to make sure it remains above the re-crystallization temperature.

To maintain a safety factor a finishing temperature is defined above the re-crystallization temperature; this is usually 50 to 100 °C (122 to 212 °F) above the re-crystallization temperature. If the temperature drops, the material must be re-heated before hot rolling.

SPECIFICATIONS

| SIZE | |

| Thick | 20.00 mm to 100.00 mm |

| Width | 750mm to 2000 mm |

| length | 2500 mm to 12500 mm |

| IF SLIT COIL | |

| Thick | 20.00 mm to 100.00 mm |

| Width | 1250 mm to 2500 mm |

| Length | 2500 mm to 12500 mm |

GRADE

2062 GradeBoiler Quality.

APPLICATION

Boiler & Pressure VesselsShip Building

Railways

Heat Exchangers

Oil & Petrochemicals

Coal & Mining

General & Heavy Engineering.